The Hänel Eco-Concept

Bringing Sustainability to Automated Storage and Retrieval

Energy-efficient systems are the key to lowering energy consumption in your warehouse, office, or factory. The actual energy consumption of automated material and file handling systems has a major impact on operating costs, amortization, and our environment.

For this reason, Hänel has always placed great emphasis on continually optimizing the energy efficiency of their vertical storage systems. From carefully selecting high-quality components and technology, to using frequency converters that use up to 50% less energy than drives powered directly from the main power supply.

The Efficient Design Principle

The Lean-Lift stores all items in height optimized positions ensuring extremely compact storage in a minimum footprint. This optimal use of storage area results in energy savings.

The vertical carousel principle of the Hänel Rotomat is energy-efficient in its very design. Using the load imbalance indicator ensures the weight distribution inside the Rotomat is balanced. As a result, very little energy is required for a rotation or travel movement. And of course, the unit always picks the shortest route automatically.

Optimizing The Energy Balance with Intelligent Concepts

Hänel constantly develops components that contribute to improving energy efficiency. The latest developments in this effort are embodied in three new technology profiles:

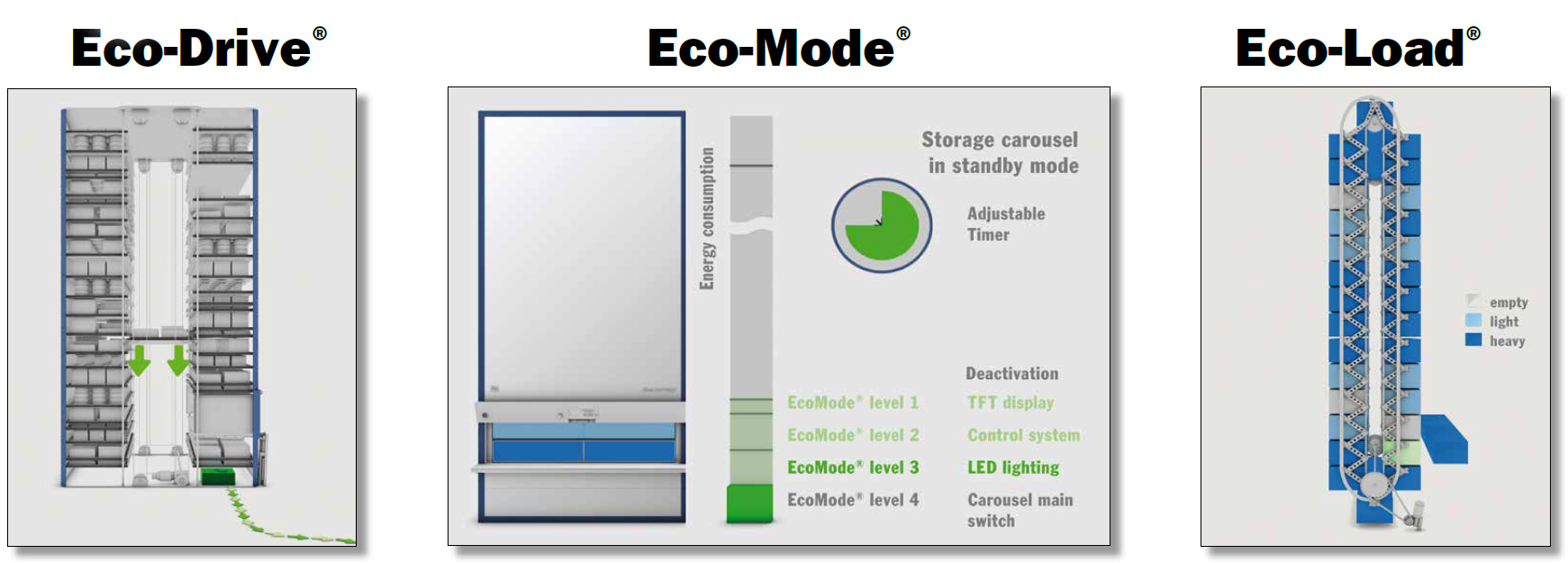

Eco-Drive

The Hänel Eco-Drive helps to save energy and reduce costs. The frequency converter uses the energy of the descending extractor and converts it back into electricity. This is then fed back into the supply system and can be used again. Depending on the rate of travel, up to 40% of the energy fed in previously for the upward run can be returned to the supply network.

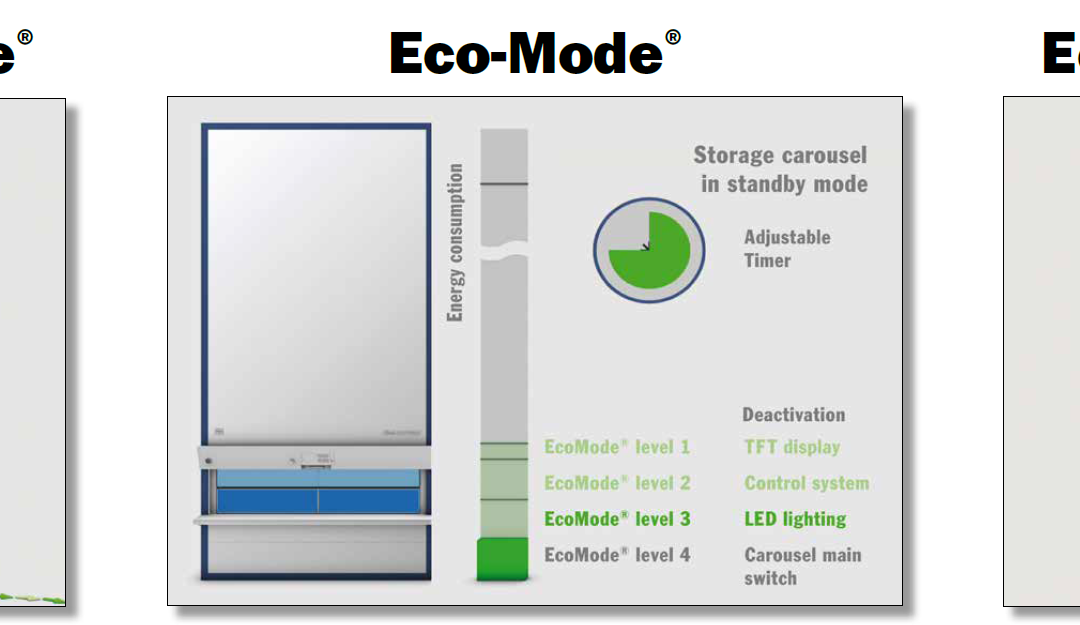

Eco-Mode

A vertical carousel that remains at standstill for long periods of time can be automatically switched to pre-set levels of standby mode chosen by the user. Systems are progressively closed down by the control system in four Eco-Mode levels. This reduces energy use to a minimum when the unit is not in operation.

Eco-Load

With Eco-Load, the Hänel microprocessor control system gives loading recommendations to the user. If these are followed, the distribution of the stored items is always evenly balanced. As a result, only minimal energy is then needed to start the storage carousel rotating.